The 1987 Topper Tuotanto padded bomber fuses Nordic functionalism, Cold War modularity, and industrial precision within civilian outerwear.

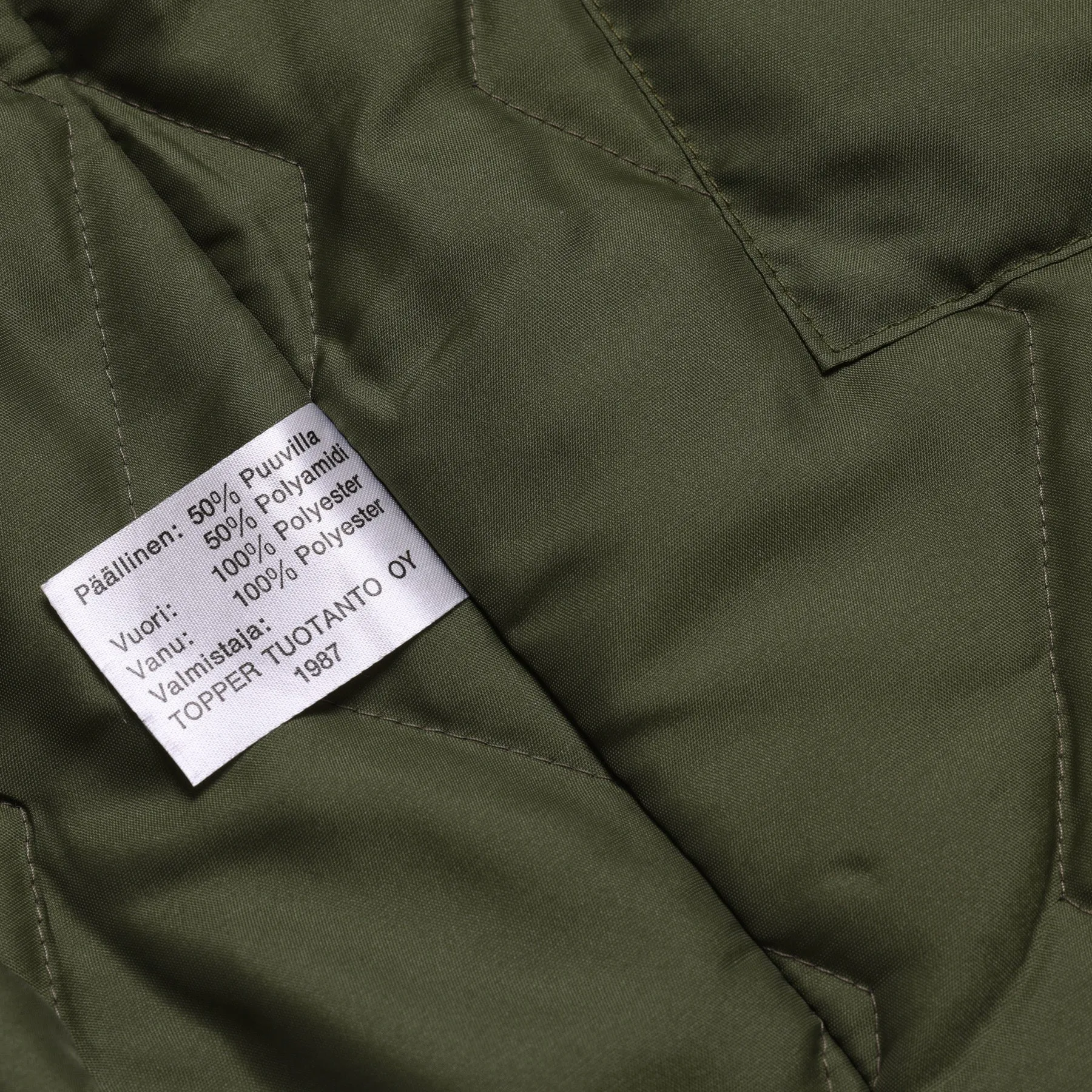

Topper Tuotanto, a Finnish manufacturer active primarily in the 1970s and 1980s, cultivated a reputation within the niche of functional outerwear, insulated workwear, and military-adjacent civilian garments, positioning itself within the broader Nordic tradition of climate-resilient utilitarian design. Rooted firmly in functional rationalism, Topper Tuotanto Oy rejected decorative artifice in favor of hardwearing materials, durable construction techniques, and sober, pragmatic modularity. This philosophical commitment is evident in the garment’s material selection, constructional solidity, and unembellished, technically articulate design ethos. Operating in parallel with regional players like Luhta and Finlayson’s technical divisions, Topper Tuotanto Oy contributed meaningfully to the Nordic functional clothing movement, helping establish a visual and structural vocabulary that prefigured the later blurring of workwear and streetwear codes. Their garments, shaped by European military surplus traditions, emphasized textile durability, simplified articulation, and modular adaptability, informing subsequent global adoptions of padded bombers and militarized outerwear within urban menswear contexts. This particular jacket, produced in 1987, classifies as a cold-weather padded bomber engineered for civilian workwear and urban commuting needs, balancing insulation, abrasion resistance, and ergonomic functionality. It features a high ribbed collar and cuffs for wind protection, a reinforced storm flap-concealed main zipper closure, multiple zip-secured pockets designed for operational utility, and a quilted insulated lining structured to stabilize body heat without sacrificing movement or volume control. The construction methodology reflects industrial technical precision: lockstitching dominates structural seams, with high-stress areas such as pocket welts and storm flaps reinforced through strategic bar-tacking. Seams are double-stitched where tensile stress is greatest, enhancing garment longevity. The lining is quilted through regular vertical stitch grids, preventing insulation migration and cold spots, while maintaining even thermal distribution. The main closure employs a heavy-gauge molded resin zipper, topstitched into a concealed placket for enhanced weather resistance and aesthetic clarity. Technical design features are executed with methodical intent. Diagonally placed chest zip pockets enhance accessibility, a hidden back yoke zipper suggests modular storage or ventilation capability, and an integrated elastic internal harness system allows the jacket to be worn backpack-style when unzipped—a feature rare for the era, anticipating later technicalwear innovations. Internally, seam allowances are pressed cleanly with minimal fabric bulk, underscoring disciplined assembly practices rare in civilian workwear of the period. Stylistically, the jacket’s lineage traces to the MA-1 bomber, originally derived from U.S. Air Force flight jackets of the 1940s–50s. Adapted through Nordic design sensibilities, this silhouette evolved for colder climates, incorporating heavier insulation, denser shell fabrics, and additional modular features. In this Finnish iteration, the militarized blueprint is tempered for urban civilian utility without diluting its technical core, aligning with broader late-1980s European trends toward soft militarization of outerwear. The fabric engineering is equally deliberate. The outer shell is a 50% cotton, 50% polyamide (nylon) high-density plain weave (~210–240 GSM), balancing cotton’s breathability and natural handfeel with polyamide’s superior tensile strength, abrasion resistance, and inherent water repellency. The shell’s slight sheen arises both from the polyamide fibers and a likely DWR treatment, enhancing environmental resilience. Inside, the lining and batting are 100% polyester, offering low moisture absorption, structural stability, and efficient thermal retention without adding excessive bulk. Comparatively, this shell fabric aligns with several historical technical textile categories: flight satin blends from early bomber jackets, modified Ventile cotton-nylon adaptations developed for military performance, plain-weave ripstop hybrids used in lightweight combat gear, and tropical military poplins designed for durability under variable climatic stresses. Textile mills such as British Millerain, Olmetex, Ventile (Stotz & Co.), and Toray Industries have historically specialized in such high-resilience, tightly woven fabrics, situating this jacket within a credible technical fabric lineage. Knit construction further supports functional aims: the ribbed collar, cuffs, and hem are produced in a double-layered circular rib knit, approximately 12-gauge tension, likely incorporating polyester or acrylic fibers to enhance abrasion resistance and long-term elasticity. This execution mirrors military knitwear standards but with a slightly coarser, more ruggedized fiber handling suited to civilian workwear demands. Structurally, the paneling configuration favors functional economy and resilience: single-piece front panels accommodate vertical zip pocket insertions; two-piece sleeves with slight anatomical curvature support ergonomic articulation; a single-piece back panel integrates the concealed yoke zipper without compromising structural integrity. Vertical welted zip pockets at the side seams provide secure storage without excessive seam disruption. The internal harness system is anchored robustly into side seams, ensuring weight distribution stability when the garment is worn off-shoulder in backpack mode. Patternmaking reflects military block logic adapted for urban civilian needs: a boxy fit with dropped shoulders, wide torso girth to accommodate layering, and a slight sleeve taper into ribbed cuffs to trap body heat. The quilted lining necessitates moderate panel shaping to preserve garment mobility without creating undue bulk, a balance deftly maintained throughout. The collar is drafted as a high ribbed stand with an integrated woven shell extension, engineered for full neck coverage against wind without excessive complexity. Assembly and finishing techniques emphasize durability and production efficiency. Seams are plain-stitched and internally overlocked; external topstitching at approximately 3 mm reinforces stress points without overwhelming the visual balance. Quilting is symmetrically applied, minimizing insulation drift and maintaining ergonomic fluidity. Reinforcements at zipper openings, pocket stress points, and collar-to-body junctions ensure the garment withstands mechanical stresses typical of daily wear. Despite utilitarian priorities, color coordination between molded zippers and the shell fabric reflects subtle attention to visual cohesion within functional frameworks. Technically, precision levels are consistently high for industrial utility production. Zipper installations are even and secure; quilting grids are symmetrical; collar attachments are firm yet clean. Material handling is skillful, avoiding seam puckering despite the challenge of dense shell and insulation layering. Design-execution consistency is strong: all elements—internal harness, modular pocketing, robust closures—work together toward the jacket’s pragmatic mission profile. Special technical features—including the elastic carry harness, reinforced back neck zipper, and robust molded hardware—further elevate the jacket’s utility logic. These elements anticipate later technicalwear trends popularized by brands like Stone Island Shadow Project and Alyx, underlining the jacket’s prescience in modular adaptability and ergonomic user experience. Conceptually, the jacket embodies Cold War-era functionalism: modularity, resilience, and adaptability against environmental uncertainties. Its olive color palette, clean geometric forms, and stripped-down detailing resonate with psychological themes of resilience, order, and pragmatic control, reflecting the militarized subconscious of its era. Artistically, it belongs to a brutalist-functional tradition in design: material truth, structural directness, and performance-driven form. Its beauty lies in its refusal of ornament, instead articulating a severe yet eloquent vision of utilitarian technicalwear. Historically anchored in 1987, during a period of global geopolitical tension and technical innovation in civilian-militarized apparel, this jacket embodies the precise intersection of necessity, innovation, and stylistic minimization that defined late-Cold-War European outerwear. In today’s market, the garment would sit squarely within the archival workwear, neo-militaria, and technical heritage spaces, aligning with brands such as Engineered Garments, Arpenteur, Nanamica, and Nigel Cabourn. The technical carry system foreshadows modular adaptations celebrated by technical-luxury labels, while the unadorned material and structural honesty position it firmly within contemporary trends privileging function-led authenticity. Ultimately, this Topper Tuotanto Oy padded bomber jacket demonstrates formidable technical competence, clear material logic, and pragmatic design execution. Its rugged structural clarity, modular adaptability, and historical authenticity ensure strong viability within contemporary vintage markets, technicalwear circles, and heritage-focused fashion subcultures that value narrative depth, functional excellence, and archival precision in outerwear.

Measurements (cm):

Chest: 60

Length: 70

Shoulder: 48

Sleeve: 64

Size Conversion (approximate)

US Men’s Size: L

EU Men’s Size: 50

SKU: 015050